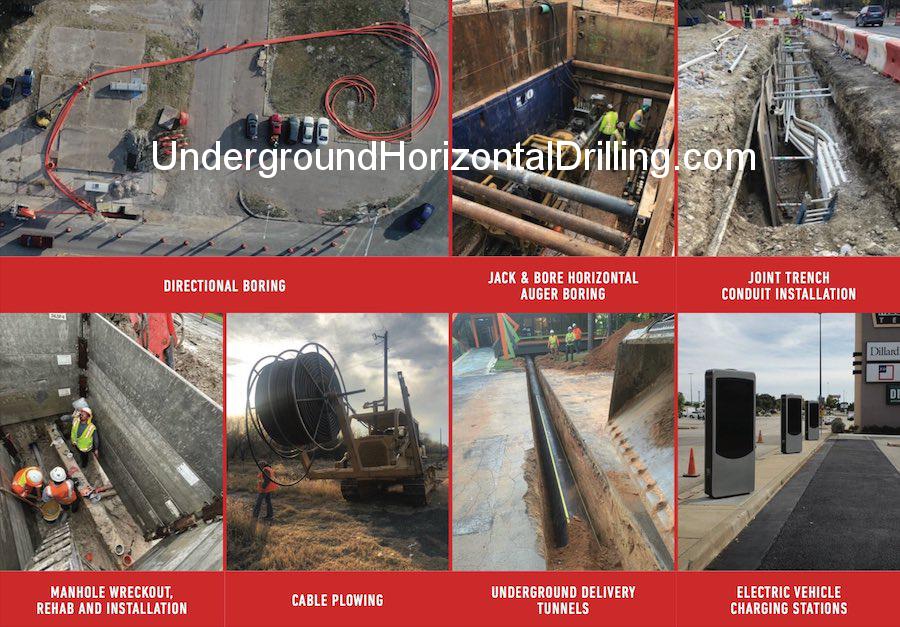

Underground Tunneling

We have experience tunneling through all types of ground conditions under roadways, buildings, railways, and natural features utilizing a wide array of tunneling techniques.

Micro-Tunneling, Tunneling, Pipe Ramming, Directional Micro-Tunneling, Shaft construction and shoring are all different tunneling methods that our teams and affiliates have used.

Since the tunneling process doesn’t require a surface entry and exit point, the overall crossing length can be reduced dramatically and thus there are very few limitations to a tunnel’s size.

Ground water, unconsolidated formations, subsurface debris and restricted workspace are also challenges that tunneling methods can be used to overcome.

Tunneling techniques are best used when the crossing distance is short, the pipe diameter is large and the construction footprint does not allow for an entry and exit angles.

Underground Horizontal Drilling Tunnel | Hand Mine Tunneling

Underground Horizontal Drilling Tunnel | Hand Mine Tunneling

Hand tunneling is the excavation and installation of fixed tunnel supports at the underground tunnel head by tunnel miners. We can build practically any shape, size or length tunnel by hand. Our tunneling methods adaptability is exceeded only by its flexibility when encountering unexpected conditions such as buried utilities or unknown or difficult soil conditions. And while the hand tunneling method may be centuries old, our excavation tools, tunnel support materials, and engineering are state of the art.

Hand tunneling is very effective in soils below the water table when combined with ground stabilization methods such as dewatering, chemical and cement grouting, and/or compressed air tunneling. Hand tunneling is generally the slowest tunneling method, yet it often provides the most risk free option to the owner when potential unknowns are a factor.

Underground Horizontal Drilling Tunnels | Conventional Tunneling

Underground Horizontal Drilling Tunnels | Conventional Tunneling

Conventional Utility Tunneling:

Conventional tunneling is a two stage process in which a temporary ground support system is constructed to allow the installation of the product pipe. The temporary tunnel liner is installed as the underground tunnel is constructed. The temporary ground support system (liner) can incorporate steel or concrete tunnel liner plates, steel ribs with wood lagging, or an all wood box culvert. Conventional tunnel workers (miners) enter the tunnel to perform the excavation and/or spoil removal. The tunnel excavation can be accomplished manually or mechanically.

Common Conventional Tunneling Questions

How accurate is underground tunneling?

How do you manage groundwater?

What impact do subsurface obstacles (boulders, buried debris, etc.) have on the tunneling process?

How much time is required to complete tunnel shaft construction?

How much time is required to mobilize a tunneling companys crew?

What is estimated production for a tunneling contractor?

What is the necessary ground covering?

Underground Horizontal Drilling Tunneling | Microtunneling

Underground Horizontal Drilling Tunneling | Microtunneling

Microtunnelling is a digging technique used to construct small utility tunnels. These small diameter tunnels make it impossible to have an operator in the machine itself. Instead the micro-tunnel boring machine (MTBM) is operated remotely.

Microtunnel boring machines are very similar to tunnel boring machines (TBM) but on a smaller scale. Usually the MTBM operator controls the machine from a control room on the surface of the ground. The Microtunneling machine and jacking frame are set up in a shaft at the required depth. The operator is given constant feedback about the microtunnel boring machines location, orientation and hydraulic devices via a computer console or CCTV camera. Most MTBMs also have video cameras set up to enable the operator to monitor activities in the jacking shaft and at the separation plant. The operator controls the MTBM and the jacking frame from the safety of the control room, which is usually situated on the surface, next to the jacking shaft.

Microtunnel Boring Machine (MTBM):

The microtunnel boring machine (MBTM) refers to the microtunnel shield jacked through the earth which excavates the ground while simultaneously installing pipe, as spoil is excavated and removed. Personnel entry is not required for routine operation.

More About Microtunneling:

Microtunneling is a trenchless construction method for installing pipelines with the following features:

Remote Controlled - the microtunnel boring machine is operated from a control panel, normally located on the surface. It simultaneously installs pipe as spoil is being excavated and removed.

Guided - The guidance system usually refers to a laser beam projected onto a target in the microtunnel boring machine, capable of installing gravity sewers or other types of pipeline to the required tolerance for line and grade.

Jacking Pipe - The process of constructing a pipeline by consecutively pushing the MTBM through the ground using a jacking system.

Face Support - Continuous pressure is provided to the face of the excavation to balance groundwater and earth pressure.

TUNNEL GROUTING SYSTEMS

Grouting systems are used to fill voids between the geological formation and installed product line or between product lines, one inside of the other. There are several reasons for grouting including increased structural integrity and heat dissipation.

Also see Pipe Ramming:

Pipe ramming is an underground construction technique for installing steel casings from a drive shaft to a reception shaft utilizing the dynamic energy from a percussion hammer attached to the end of the pipe. A continuous casing support is provided and over-excavation or water is not required.